There are many different types of cabinetry—built-ins that are secured to the wall (think kitchen cabinets), moveable modular cabinets, wall cabinets, and base cabinets. There is also a wide range of styles from cabinet fronts finished with ornate trim, classic simple looks like the shaker style door, and minimalist modern styles with sleek inset doors. But, they all start with one essential piece—the cabinet box.

In this article, you’ll learn now to build a frameless style cabinet box and flat panel door, as taught by cabinet builder Ken DeCost in his online course Introduction to Cabinetry. Ken prefers the frameless style because of its simplicity, approachability, and clean look, but the opportunities to get creative with cabinetry are endless.

“People now have access to a lot of the same tooling that high-end cabinet shops and mass-produced furniture companies have right in their own small shop, and I think that we’re entering the next stage of people really valuing that handmade furniture.” – Ken DeCost

Anatomy of a cabinet

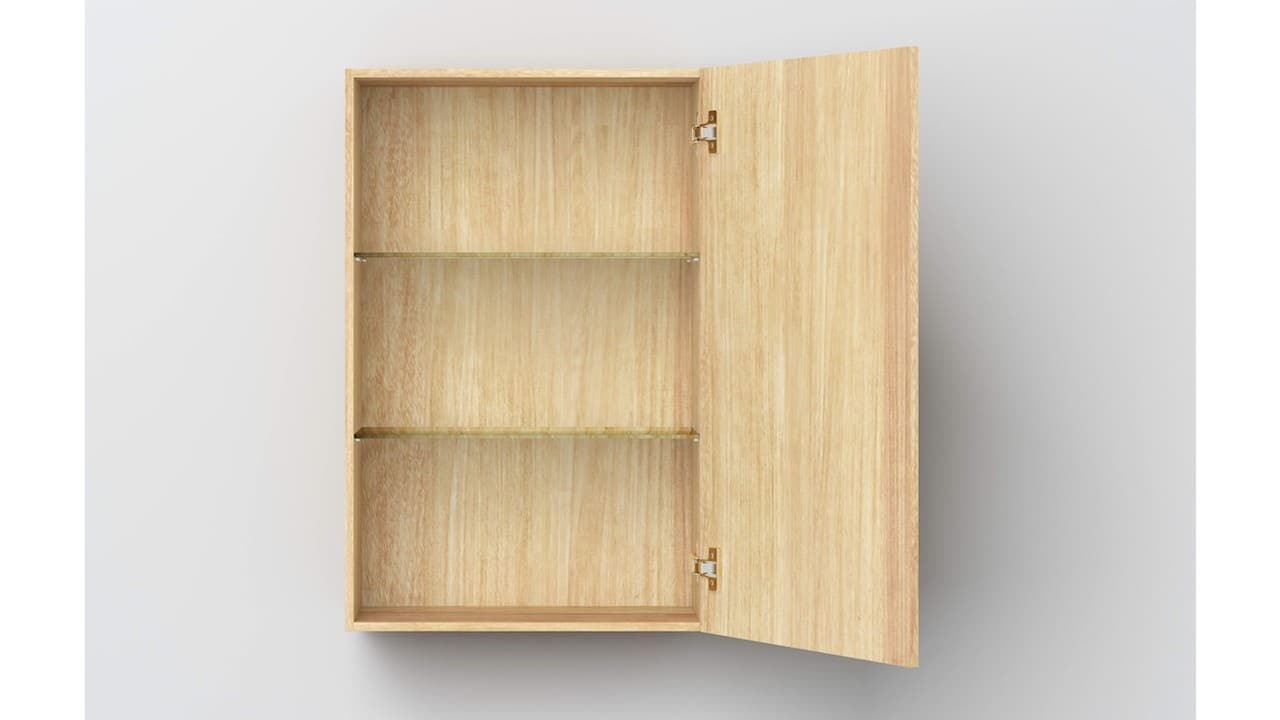

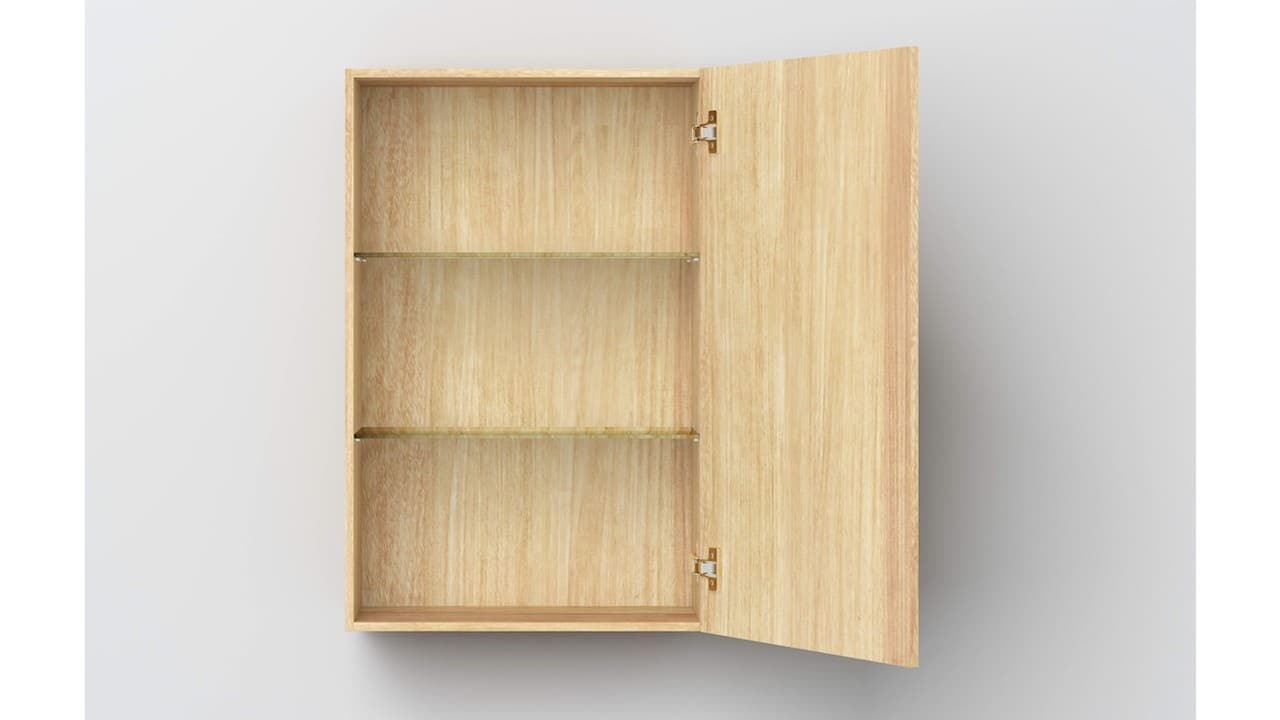

There are many different types of cabinets, but the basic components remain the same. All cabinets are composed of a cabinet box and a cabinet door mounted with some type of hinge.

Cabinet box or case

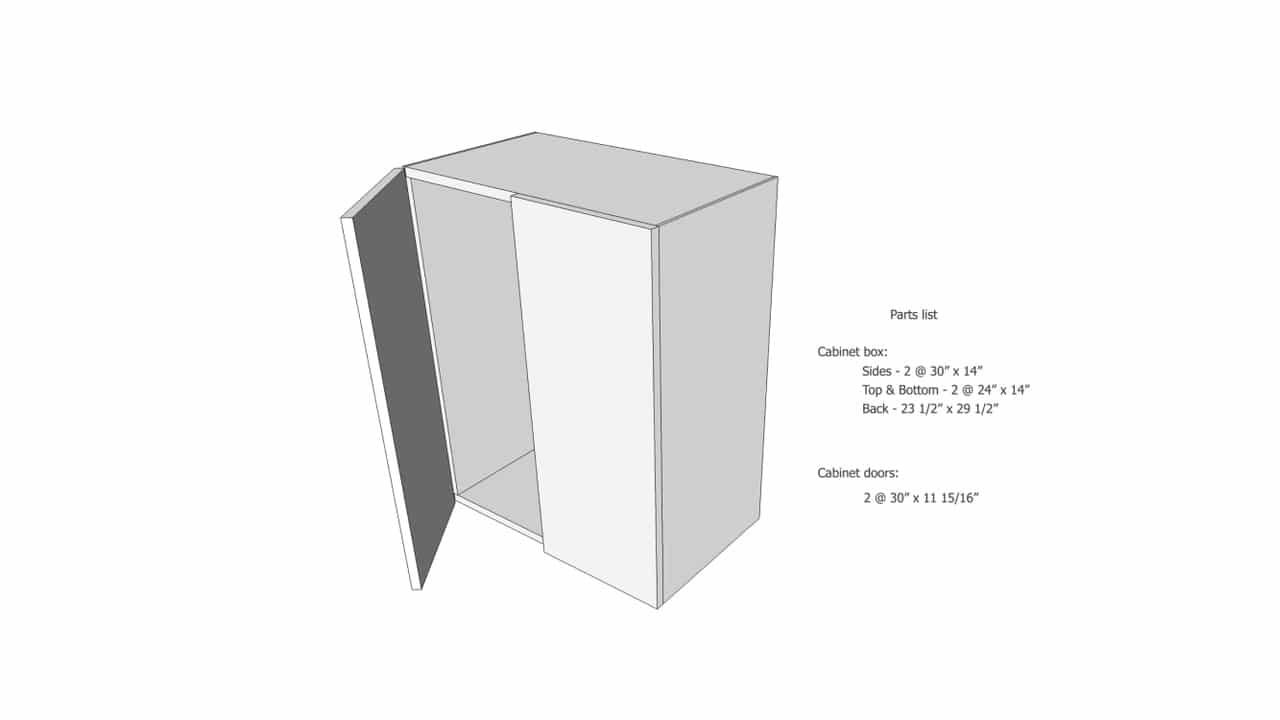

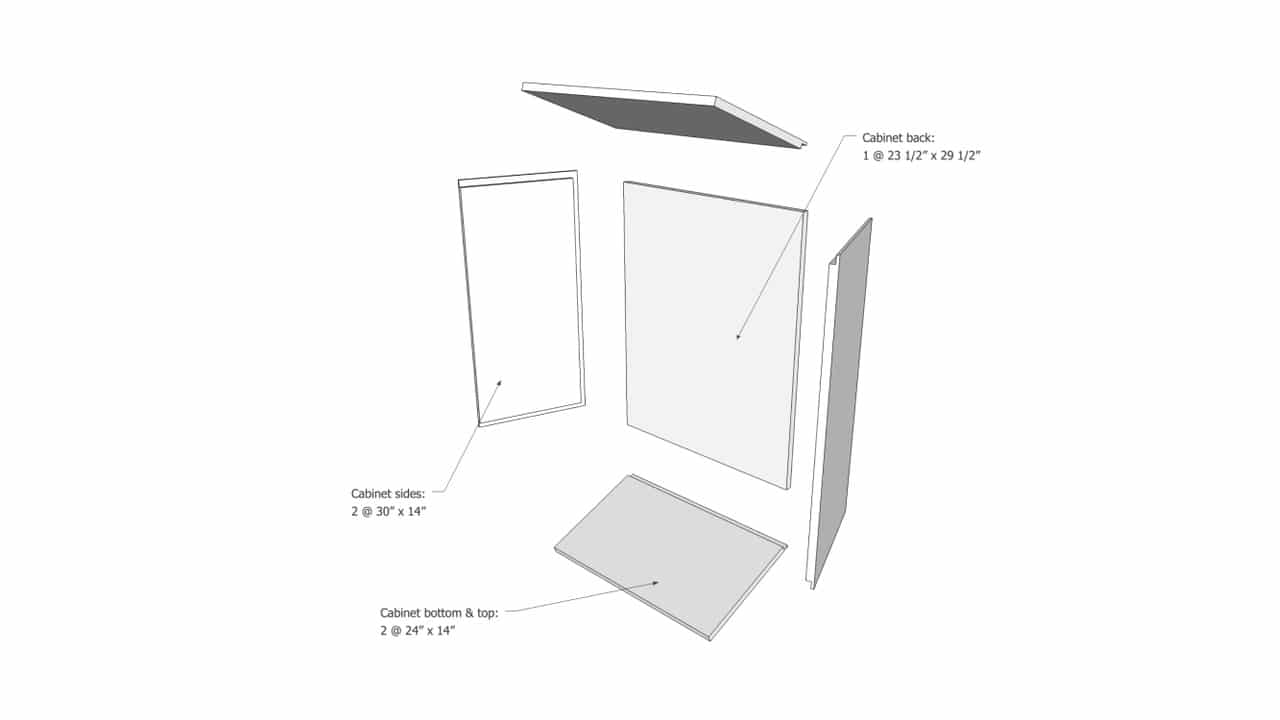

The cabinet box, also called the cabinet case, is the foundation of any cabinet, and it’s as simple as the name implies. It’s a box shape made of two side panels, a top and bottom panel, and a back panel.

Face frame style cabinet boxes have a more traditional look but require building the frame piece that is visible when the doors are open and closed. Keep in mind that this style may require you to drill pocket holes and use the specialty pocket hole screw type.

When choosing between face frame or frameless cabinets, consider the style of the rest of your home interior and choose the look that fits best.

Doors

While there are many different styles of cabinet doors, the two general categories are 5 piece and flat panel. The both offer the same full access to the inside of the cabinet so the choice is about aesthetics.

- 5 piece or shaker door: The 5 piece door style is also commonly referred to as a shaker door or shaker style door. It’s a simple, classic cabinet style and the front profile is endlessly customizable.

- Flat panel or slab door: A flat panel door does not have the frame-like detail of a 5 piece style door. It is made from one solid substrate like painted or veneered MDF (engineered wood) and offers a clean, modern look. They are much easier to fabricate than 5 piece doors and more budget-friendly.

Door mounts

There are two main styles of door mount—inset and overlay—and the functionality is the same for both. The choice is more about aesthetics, or what you want to see (or do not want to see) when the cabinet door is open or closed.

- Inset: The cabinet door is flush with and on the same plane as the cabinet frame and the frame surrounds the entire cabinet door.

- Full overlay: Also simply called overlay, a full overlay door covers the entire cabinet width when closed, and the inside wood edge of the cabinet box is exposed when the door is open.

- Partial overlay: In partial overlay, the cabinet door partially covers the cabinet box when the door is closed, and the inside wood edge of the cabinet box is exposed when the door is open.

Edges

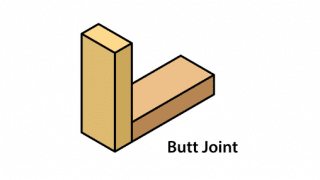

How the pieces of the cabinet are joined together is called joinery and the edges of the cabinet will often reveal what type of joinery was used.

Mitered edges: For cabinet styles where the wood edges will be exposed, mitered corners help achieve a clean, finished look. For example, you might see this technique on an upper cabinet where the joint will be exposed and at eye level.

Hinges

It is critical that the hinge type you use matches the overlay style that you are building so that the door is mounted with the proper amount of clearance. Ken prefers European hinge styles which are installed on the interior of the cabinet and concealed when the door is closed. They work with inset, partial, and full overlay style doors and offer flexibility and greater room for adjustments.

Decorative hardware

Hardware attaches to the front of the cabinet and is the mechanism to open and close the doors. In the cabinet building industry it is referred to as decorative hardware. There are infinite options for handles, knobs, pulls, or routed in handles, and the choice is largely aesthetic. The hardware should fit the personality of the home, any existing cabinet or drawer fronts, and the homeowner’s preference. It’s the last item to install but is an important final touch.

Step-by-step guide to building cabinets

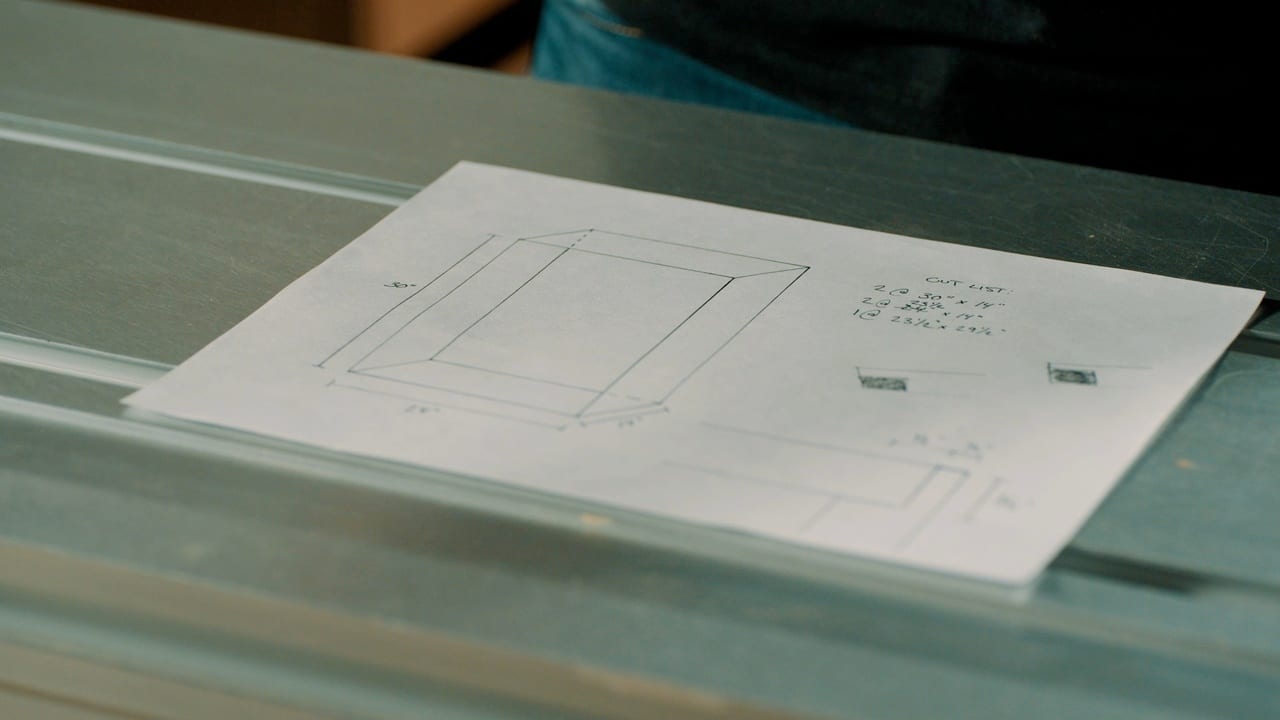

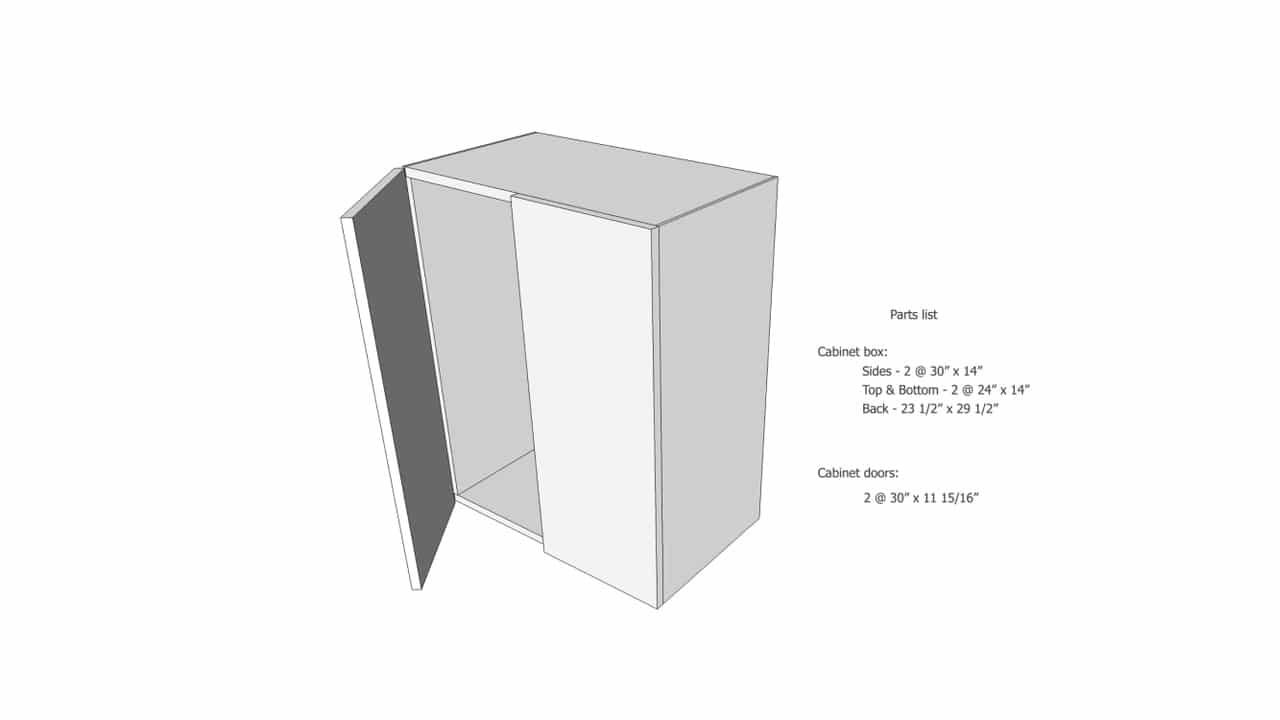

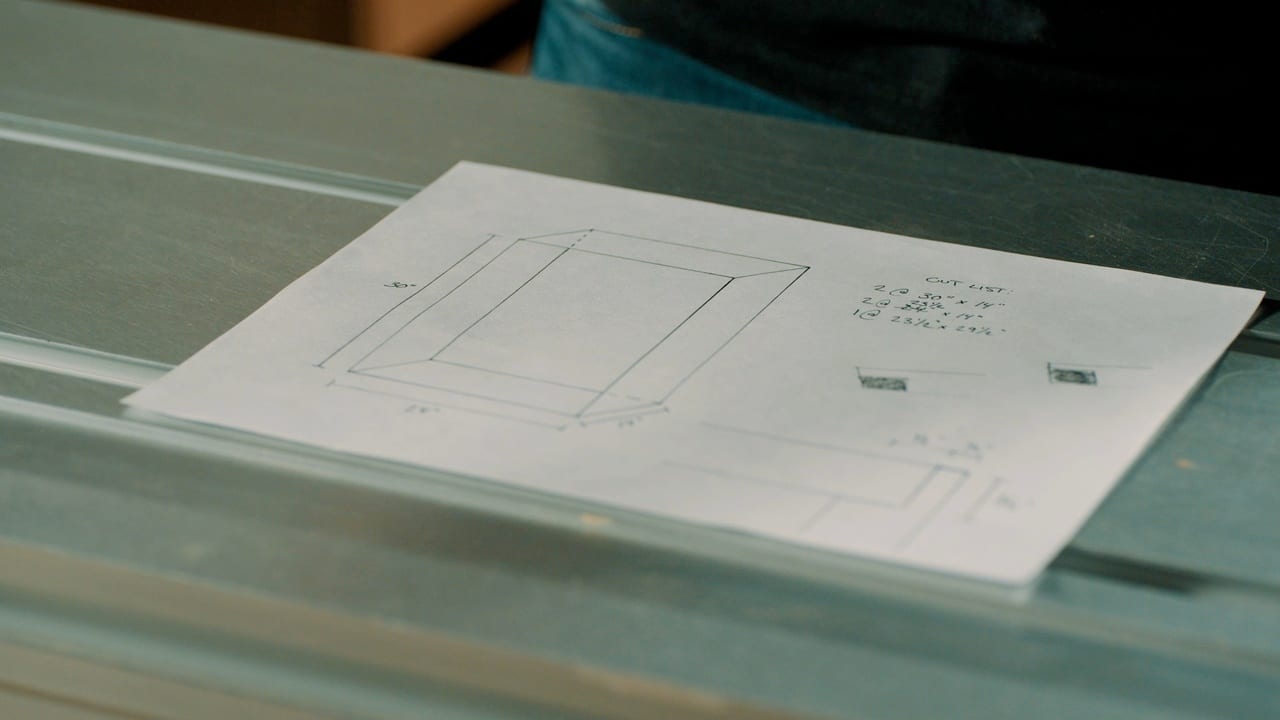

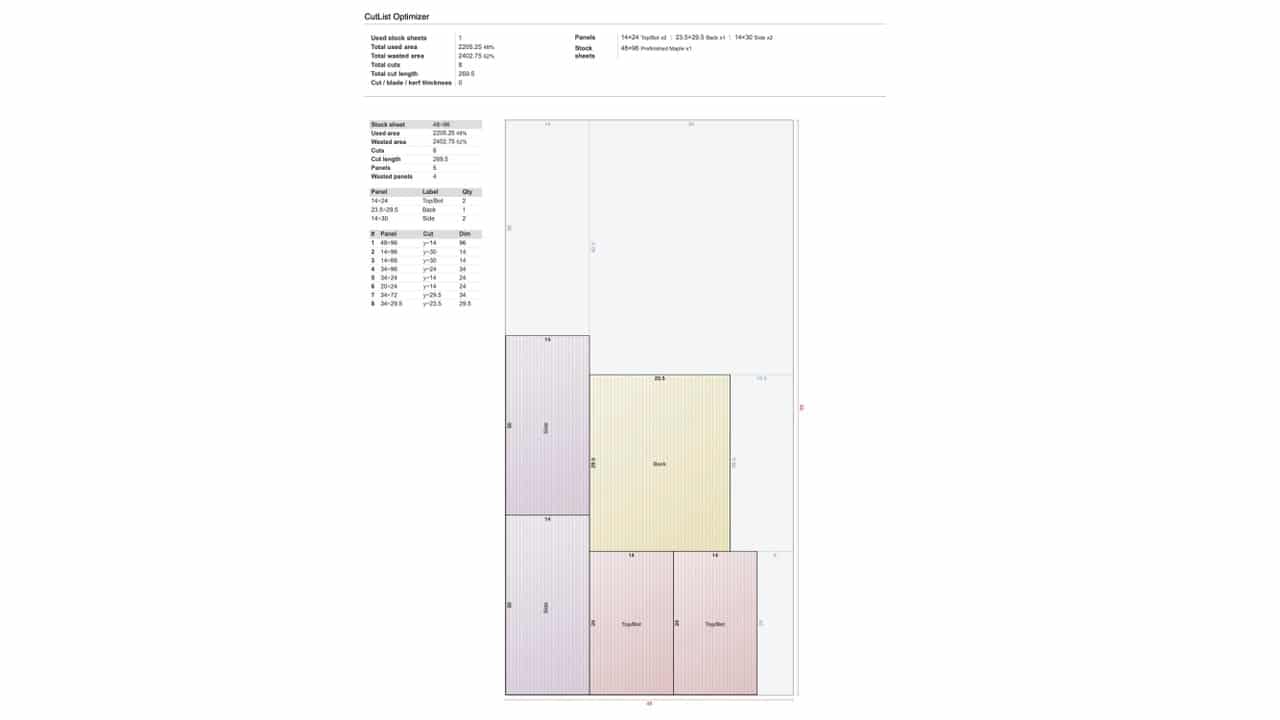

The cabinet box will consist of 5 basic pieces: top and bottom pieces cut the same, two sides cut the same, and a third cutting setup for the back piece.

Step 1: Set up safely

- Always wear safety glasses and earplugs while using the table saw.

- Connect to a dust collection system, or work outside to prevent breathing in dust particles.

- Make sure the table saw blade is square with the table using a digital angle gauge or a speed square. Use the table saw’s tilting arbor to adjust as needed.

- Never cross your arm over the blade area.

- Use a push stick for tight cuts.

- Use a sacrificial fence when the saw blade may come in contact with the actual fence.

- Make multiple passes for great lengths of wood.

Step 2: Cut the panels

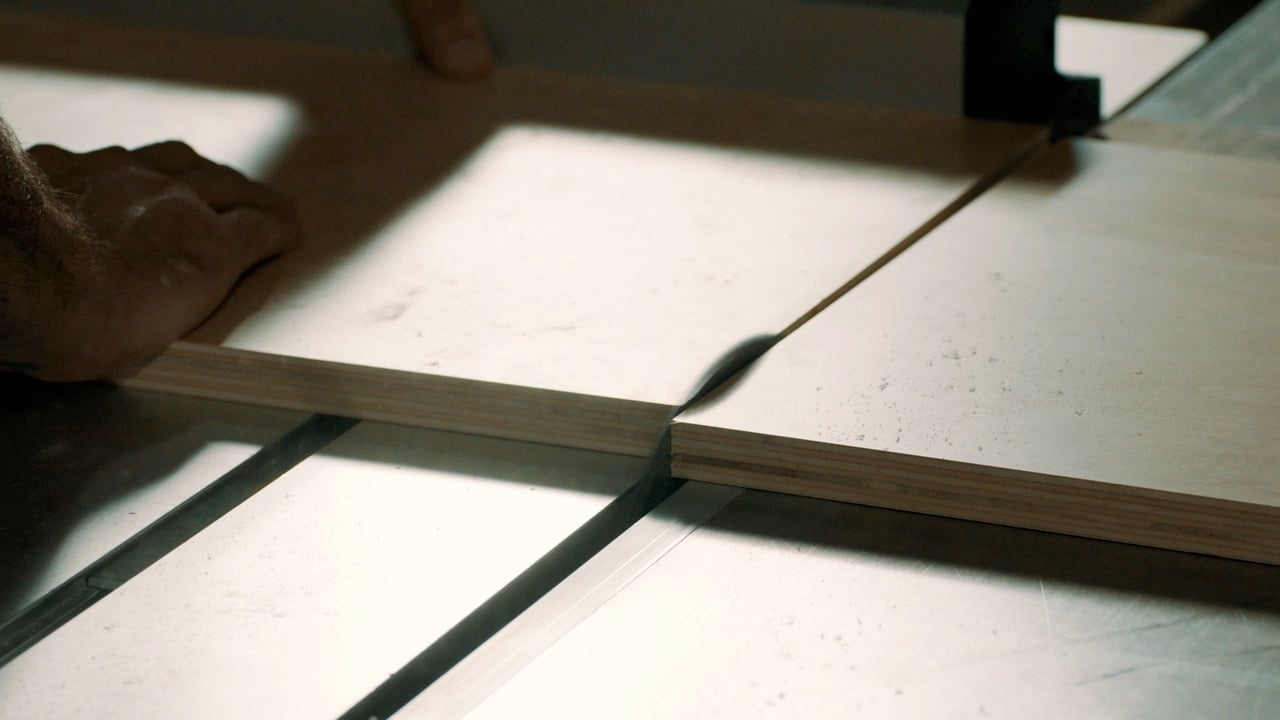

First start with the rip cuts. A rip cut is a cut that runs in the same direction as the grain and is typically the long cut on a piece of wood. Measure from the fence to the inside (or rip side) of the saw blade and set your fence to 14 inches wide. Cut the sides, top, and bottom to width. Double check measurements once complete.

Tip: For a continuous wood grain look, aim for a vertical grain on the side panels and back piece and horizontal grain across the top and bottom pieces.

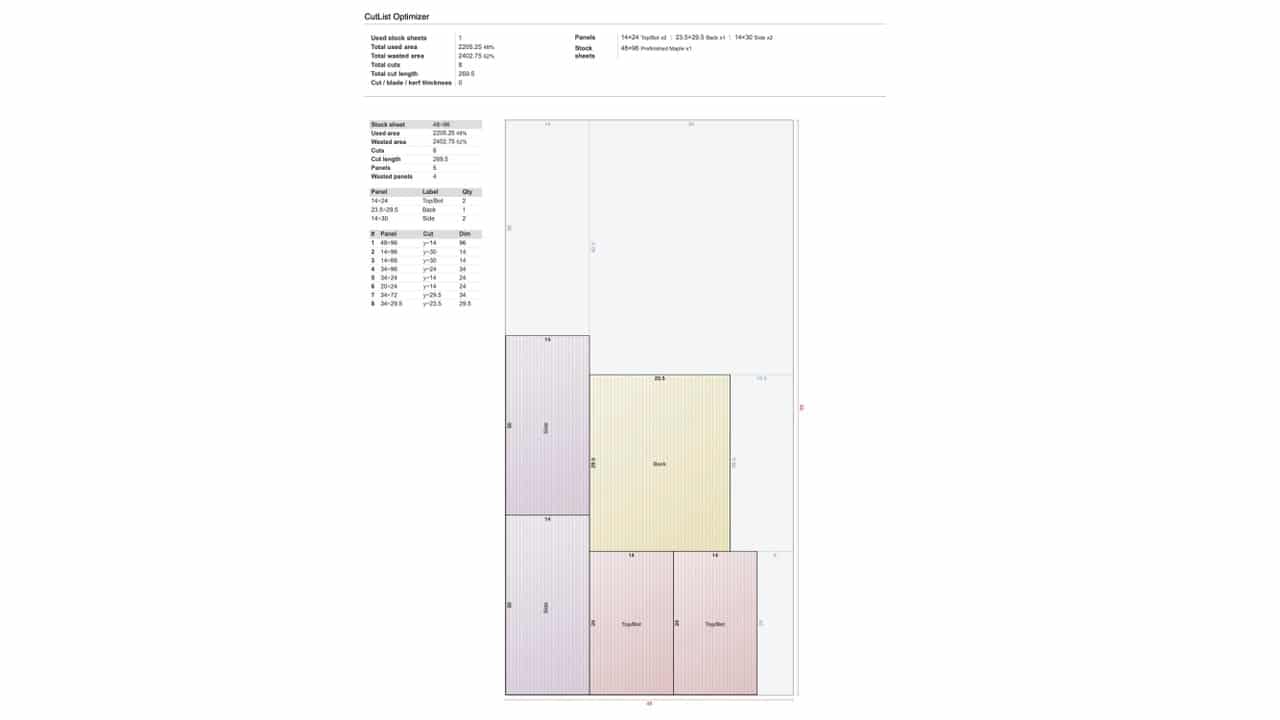

Cut List:

Learn about the anatomy of cabinets, common materials, and the proper techniques to build quality pieces with cabinet maker Ken DeCost in MT Copeland’s Introduction to Cabinetry online course.

There are many different types of cabinetry—built-ins that are secured to the wall (think kitchen cabinets), moveable modular cabinets, wall cabinets, and base cabinets. There is also a wide range of styles from cabinet fronts finished with ornate trim, classic simple looks like the shaker style door, and minimalist modern styles with sleek inset doors. But, they all start with one essential piece—the cabinet box.

In this article, you’ll learn now to build a frameless style cabinet box and flat panel door, as taught by cabinet builder Ken DeCost in his online course Introduction to Cabinetry. Ken prefers the frameless style because of its simplicity, approachability, and clean look, but the opportunities to get creative with cabinetry are endless.

“People now have access to a lot of the same tooling that high-end cabinet shops and mass-produced furniture companies have right in their own small shop, and I think that we’re entering the next stage of people really valuing that handmade furniture.” – Ken DeCost

Anatomy of a cabinet

There are many different types of cabinets, but the basic components remain the same. All cabinets are composed of a cabinet box and a cabinet door mounted with some type of hinge.

Cabinet box or case

The cabinet box, also called the cabinet case, is the foundation of any cabinet, and it’s as simple as the name implies. It’s a box shape made of two side panels, a top and bottom panel, and a back panel.

Face frame style cabinet boxes have a more traditional look but require building the frame piece that is visible when the doors are open and closed. Keep in mind that this style may require you to drill pocket holes and use the specialty pocket hole screw type.

When choosing between face frame or frameless cabinets, consider the style of the rest of your home interior and choose the look that fits best.

Doors

While there are many different styles of cabinet doors, the two general categories are 5 piece and flat panel. The both offer the same full access to the inside of the cabinet so the choice is about aesthetics.

- 5 piece or shaker door: The 5 piece door style is also commonly referred to as a shaker door or shaker style door. It’s a simple, classic cabinet style and the front profile is endlessly customizable.

- Flat panel or slab door: A flat panel door does not have the frame-like detail of a 5 piece style door. It is made from one solid substrate like painted or veneered MDF (engineered wood) and offers a clean, modern look. They are much easier to fabricate than 5 piece doors and more budget-friendly.

Door mounts

There are two main styles of door mount—inset and overlay—and the functionality is the same for both. The choice is more about aesthetics, or what you want to see (or do not want to see) when the cabinet door is open or closed.

- Inset: The cabinet door is flush with and on the same plane as the cabinet frame and the frame surrounds the entire cabinet door.

- Full overlay: Also simply called overlay, a full overlay door covers the entire cabinet width when closed, and the inside wood edge of the cabinet box is exposed when the door is open.

- Partial overlay: In partial overlay, the cabinet door partially covers the cabinet box when the door is closed, and the inside wood edge of the cabinet box is exposed when the door is open.

Edges

How the pieces of the cabinet are joined together is called joinery and the edges of the cabinet will often reveal what type of joinery was used.

Mitered edges: For cabinet styles where the wood edges will be exposed, mitered corners help achieve a clean, finished look. For example, you might see this technique on an upper cabinet where the joint will be exposed and at eye level.

Hinges

It is critical that the hinge type you use matches the overlay style that you are building so that the door is mounted with the proper amount of clearance. Ken prefers European hinge styles which are installed on the interior of the cabinet and concealed when the door is closed. They work with inset, partial, and full overlay style doors and offer flexibility and greater room for adjustments.

Decorative hardware

Hardware attaches to the front of the cabinet and is the mechanism to open and close the doors. In the cabinet building industry it is referred to as decorative hardware. There are infinite options for handles, knobs, pulls, or routed in handles, and the choice is largely aesthetic. The hardware should fit the personality of the home, any existing cabinet or drawer fronts, and the homeowner’s preference. It’s the last item to install but is an important final touch.

Step-by-step guide to building cabinets

The cabinet box will consist of 5 basic pieces: top and bottom pieces cut the same, two sides cut the same, and a third cutting setup for the back piece.

Step 1: Set up safely

- Always wear safety glasses and earplugs while using the table saw.

- Connect to a dust collection system, or work outside to prevent breathing in dust particles.

- Make sure the table saw blade is square with the table using a digital angle gauge or a speed square. Use the table saw’s tilting arbor to adjust as needed.

- Never cross your arm over the blade area.

- Use a push stick for tight cuts.

- Use a sacrificial fence when the saw blade may come in contact with the actual fence.

- Make multiple passes for great lengths of wood.

Step 2: Cut the panels

First start with the rip cuts. A rip cut is a cut that runs in the same direction as the grain and is typically the long cut on a piece of wood. Measure from the fence to the inside (or rip side) of the saw blade and set your fence to 14 inches wide. Cut the sides, top, and bottom to width. Double check measurements once complete.

Tip: For a continuous wood grain look, aim for a vertical grain on the side panels and back piece and horizontal grain across the top and bottom pieces.

Cut List:

Learn about the anatomy of cabinets, common materials, and the proper techniques to build quality pieces with cabinet maker Ken DeCost in MT Copeland’s Introduction to Cabinetry online course.

Then reset the fence to the back panel width (23 ½ inches) and repeat the ripping process.

Step 3: Make cuts for joinery

There are many joinery techniques to construct a cabinet box like hidden mortise and tenon joints done on a CNC machine, half-lap dado joints done on a table saw, or a series of dowels or dominoes. Ken uses a rabbet joint, which is similar to a dado joint.

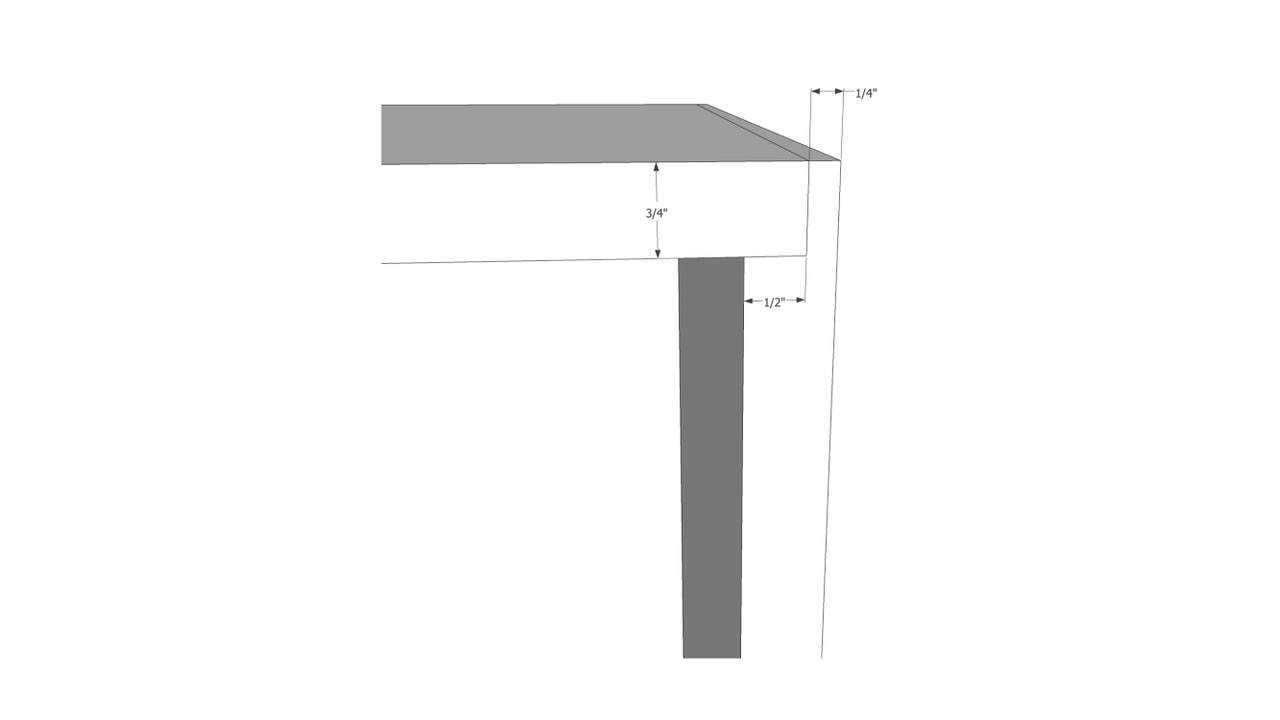

Rabbet joint dimensions:

- Swap out the regular saw blade to a dado stack. The dado blade width should be a little over the thickness of the ¾ inch plywood. Check the blade for square and adjust as necessary.

- The depth will be ½ inch in order to leave a ¼ inch of space for the tongue.

- Lower the blade completely and clamp a sacrificial fence to the rip fence to ensure that the cut goes through the entire thickness of the wood (and a little bit into the sacrificial fence).

- Switch from a tape measure to a metal ruler for more accurate measurements and set the dado to ½ inch depth. Run a few test cuts and measure to confirm that there is ¼ inch ledge.

- Dado out the backs of all four pieces and only the tops and bottoms of the side pieces. Cut with the pieces face down so that the cuts are on the inside of the cabinet.

Step 4: Assemble the cabinet box

To assemble, place the top piece’s rabbet edge down and facing what will be the center of the cabinet box. Marry the top and side pieces by sliding them into the rabbet cuts. Then add a clamp across the top piece and attached sides.

Pre-drill the countersunk hole and then drive in the screw at one joint. Repeat for the other side. Move back and forth alternating between each of the cabinet sides and installing a screw every few inches. When you get to the final hole, make sure you are clearing the rabbet cut by moving up an extra ¾ inch.

Unclamp, rotate the cabinet, add the bottom piece and repeat the process. Run your hands along the inside of the cabinet corners to make sure you didn’t blow out any of the wood edges with the screws.

Repeat the pre-drilling and drilling process that you did for the side panels, taking care to stay in the center of the panel edges.

Tip: Make a shelf pin template to pre-drill interior shelving holes before you begin assembly. If you’re not using a standalone machine for this, use the template after the cabinet is assembled.

Step 5: Finish the edges

Edge banding is a thin wood veneer material that will cover the exposed grain of the plywood edges along the front edge of the cabinet. There are many different types of edge banding and ways to apply it. Ken uses an iron-on application in a prefinished maple that matches the interior of the cabinet box.

Start with the side panels so that the edge banding runs long. Make sure edges are debris and dust free. Set iron to medium with a dry (no steam) setting. Lay the edge banding down and apply light pressure directly to the banding. Use a wooden block to smooth out any bubbles. Lightly roll the iron along the edges to finish.

Learn about the anatomy of cabinets, common materials, and the proper techniques to build quality pieces with cabinet maker Ken DeCost in MT Copeland’s Introduction to Cabinetry online course.

Tip: If you are having trouble with the edge banding, warm it up, pull it off and start over.

After finishing the cabinet sides, move along to the tops and bottom. Cut the edge banding using a speed square so that it evenly butts up against the side panel banding that you already installed. Carefully finish the corners where the edge banding meets and use the speed square to make the final cut.

The final finishing step for the cabinet box is light sanding that prevents the edge banding from lifting off. Lightly roll a fine sandpaper on the edges avoiding the prefinished material.

Step 6: Build cabinet doors

Since this is a cabinet with a flat panel door design (also known as a slab door), building the doors is similar to cutting and finishing the cabinet panels. Cut two identical panels with the wood grain running vertically and finish the edges with banding. Install the door hinges and pre-drill the holes for the hardware. Now your cabinet is ready to install.

It’s much easier to install cabinets without the doors attached. Slide the doors off their hinges before you begin installing and reattach the doors once your cabinets are in place. Once the doors are on, finish with a knob, pull, or handle of your choice.

MT Copeland offers video-based online classes that give you a foundation in construction fundamentals with real-world applications, like building cabinets. Classes include professionally produced videos taught by practicing craftspeople, and supplementary downloads like quizzes, blueprints, and other materials to help you master the skills.