When it comes to making watertight connections between plumbing pipes, fittings, and fixtures, plumbers often rely on a method called soldering. This method makes quick, strong, and watertight joints in potable and nonpotable water systems on specific types of pipes.

What is soldering?

Soldering, also known as “sweating,” is a method of joining two pieces of copper together (usually water lines). Using high heat, a plumber joins the pipes with filler metal called solder, which is a flexible metal wire, and a paste called flux, which draws the melted solder into the joint helping to properly seal the connection or joint. Unlike welding, where the two pieces of metal melt together, soldering leaves the copper intact but joins them with melted metal.

When soldering two pipes, the plumber first cleans the fitting and pipe and then applies flux to the inside of the fitting and to the outside of the pipe. Then, using a torch, the plumber heats the joint to around 450 to 500 degrees Fahrenheit (the melting point of the metal solder). Once the joint is hot enough, the plumber then touches the tip of the solder wire to the joint to melt the solder, which allows the flux to pull the solder into the joint. As the joint cools, the solder hardens and creates a watertight seal.

Generally speaking, soldering is used to join pipes that carry drinking water, also known as potable water. For that reason, it’s important to use a lead-free solder specifically labeled for use on copper pipes. Leaded solder does exist (though less common) and is for other uses, such as soldering electronics.

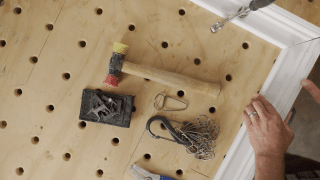

What tools do you need for soldering plumbing pipes?

Soldering plumbing pipes requires a special set of tools:

- Emery cloth is a piece of metal mesh used to clean the end of the pipe before soldering. This helps clean any accumulated dirt and oil, and clean any corrosion from the pipe that may hinder the soldering process and cause pipes to leak.

- Fitting brushes clean the inside of a fitting, and they come in sizes specific to pipe diameters. Similar to the emery cloth, this helps clean the inside of the fittings to better facilitate soldering the pipes together. Be sure you have fitting brushes that are the correct diameter for the pipe you are joining together.

- A pipe cutter features a small cutting wheel and a set of jaws that tighten to cut pipes to length without bending the pipe or leaving burrs behind.

- Pipe reamers can remove any small burrs that do remain, as they can hinder a good seal.

- Acid brushes are soft-bristled brushes with metal handles that the user can dip into the flux to then apply the flux inside the fitting and on the outside of the pipe. These are sometimes called flux brushes or solder brushes.

- A propane torch is a tool you use to heat the pipe and joint beyond the melting point of the solder.

- Lighting a propane torch requires an ignitor of some type, such as a lighter or striker.

- Having a fire extinguisher on hand is important when working with a propane torch, as the possibility of unintentionally igniting a fire is elevated when working with intense flames and high temperatures.

- Position a piece of fire cloth behind the pipe if you’re soldering in tight quarters.

- A spray bottle filled with water is also good to keep around, as you can dampen any wood studs or materials before soldering to prevent burning.

- Heat-resistant gloves to protect your hands and goggles to protect your eyes.

How to solder a copper pipe

1. Cut the pipe to size and ream the burrs

Use the pipe cutter to cut the pipe to length. Ensure that it’s long enough to fit inside the fittings. Use the pipe reamer to remove any burrs from the fresh cut.

2. Clean the pipe and fitting

Corrosion, oxidation, and carbon can prevent a good seal. To avoid this, clean the ends of the pipe well. Wrap the emery cloth around the end of the pipe and hold it in your hand. Twist the end of the pipe back and forth in the cloth until it’s perfectly clean. Clean the fitting by twisting the appropriately sized fitting brush inside the fitting until it’s clean.

3. Apply flux to the fitting and pipe

Using the acid brush, apply flux to the inside of the fitting and around the outside of the pipe. Slide the pipe into the fitting and twist it one-half turn to ensure the flux spreads around the joint. This is also a good time to position the fire cloth behind the joint and dampen anything that can burn with the spray bottle.

4. Prepare the solder

Prepare the solder by unraveling about 8 inches from the spool. Bend the solder downward approximately 2 inches in from the end of the solder wire.

When it comes to making watertight connections between plumbing pipes, fittings, and fixtures, plumbers often rely on a method called soldering. This method makes quick, strong, and watertight joints in potable and nonpotable water systems on specific types of pipes.

What is soldering?

Soldering, also known as “sweating,” is a method of joining two pieces of copper together (usually water lines). Using high heat, a plumber joins the pipes with filler metal called solder, which is a flexible metal wire, and a paste called flux, which draws the melted solder into the joint helping to properly seal the connection or joint. Unlike welding, where the two pieces of metal melt together, soldering leaves the copper intact but joins them with melted metal.

When soldering two pipes, the plumber first cleans the fitting and pipe and then applies flux to the inside of the fitting and to the outside of the pipe. Then, using a torch, the plumber heats the joint to around 450 to 500 degrees Fahrenheit (the melting point of the metal solder). Once the joint is hot enough, the plumber then touches the tip of the solder wire to the joint to melt the solder, which allows the flux to pull the solder into the joint. As the joint cools, the solder hardens and creates a watertight seal.

Generally speaking, soldering is used to join pipes that carry drinking water, also known as potable water. For that reason, it’s important to use a lead-free solder specifically labeled for use on copper pipes. Leaded solder does exist (though less common) and is for other uses, such as soldering electronics.

What tools do you need for soldering plumbing pipes?

Soldering plumbing pipes requires a special set of tools:

- Emery cloth is a piece of metal mesh used to clean the end of the pipe before soldering. This helps clean any accumulated dirt and oil, and clean any corrosion from the pipe that may hinder the soldering process and cause pipes to leak.

- Fitting brushes clean the inside of a fitting, and they come in sizes specific to pipe diameters. Similar to the emery cloth, this helps clean the inside of the fittings to better facilitate soldering the pipes together. Be sure you have fitting brushes that are the correct diameter for the pipe you are joining together.

- A pipe cutter features a small cutting wheel and a set of jaws that tighten to cut pipes to length without bending the pipe or leaving burrs behind.

- Pipe reamers can remove any small burrs that do remain, as they can hinder a good seal.

- Acid brushes are soft-bristled brushes with metal handles that the user can dip into the flux to then apply the flux inside the fitting and on the outside of the pipe. These are sometimes called flux brushes or solder brushes.

- A propane torch is a tool you use to heat the pipe and joint beyond the melting point of the solder.

- Lighting a propane torch requires an ignitor of some type, such as a lighter or striker.

- Having a fire extinguisher on hand is important when working with a propane torch, as the possibility of unintentionally igniting a fire is elevated when working with intense flames and high temperatures.

- Position a piece of fire cloth behind the pipe if you’re soldering in tight quarters.

- A spray bottle filled with water is also good to keep around, as you can dampen any wood studs or materials before soldering to prevent burning.

- Heat-resistant gloves to protect your hands and goggles to protect your eyes.

How to solder a copper pipe

1. Cut the pipe to size and ream the burrs

Use the pipe cutter to cut the pipe to length. Ensure that it’s long enough to fit inside the fittings. Use the pipe reamer to remove any burrs from the fresh cut.

2. Clean the pipe and fitting

Corrosion, oxidation, and carbon can prevent a good seal. To avoid this, clean the ends of the pipe well. Wrap the emery cloth around the end of the pipe and hold it in your hand. Twist the end of the pipe back and forth in the cloth until it’s perfectly clean. Clean the fitting by twisting the appropriately sized fitting brush inside the fitting until it’s clean.

3. Apply flux to the fitting and pipe

Using the acid brush, apply flux to the inside of the fitting and around the outside of the pipe. Slide the pipe into the fitting and twist it one-half turn to ensure the flux spreads around the joint. This is also a good time to position the fire cloth behind the joint and dampen anything that can burn with the spray bottle.

4. Prepare the solder

Prepare the solder by unraveling about 8 inches from the spool. Bend the solder downward approximately 2 inches in from the end of the solder wire.

5. Heat the joint

With a fire extinguisher nearby, use an ignitor or striker to light the torch. Adjust the gas valve so the flame is relatively short (just an inch or so long). Be careful not to burn anything behind or around the pipe, move the torch back and forth across the fitting to heat it.

6. Solder the joint

Every few seconds, tap the tip of the solder wire against the joint to see if it’s hot enough for soldering. The joint is ready when the solder melts. Continue to apply heat while working the tip of the soldering wire around the joint. The flux will allow the solder to flow into the joint, but be sure to give it full coverage. Use the solder wire to remove the ball of solder hanging off the bottom of the joint for a professional look.

7. Clean up

Remove the torch from the joint and shut it off. Carefully place it somewhere that it cannot burn or melt anything nearby. Cleaning up the joint is about more than good looks. Verdigris, the same green oxidation found on old pennies, can occur if excess flux remains on the pipe, and it can eat away at the copper pipe. Once the pipe is cool, use a rag to remove the excess flux.

Most people can learn to solder copper pipe quickly, in just an hour’s time. But mastering soldering takes a while. Don’t get discouraged if it doesn’t work at first or your pipe joints don’t look like the ones in a how-to magazine. Keep at it, be safe, and practice often.

What’s the difference between soldering plumbing and soldering electronics?

Soldering plumbing pipes is different from soldering electronic chips and boards. The two methods utilize different materials, tools, and techniques. Plumbing soldering requires acid-based flux, which the plumber applies before soldering. Electrical soldering typically utilizes rosin-core solder, and it already has flux inside its core. Also, soldering plumbing pipes requires a torch, while electrical soldering requires a soldering iron.

MT Copeland offers video-based online classes that give you a foundation in construction fundamentals with real-world applications, like plumbing. Classes include professionally produced videos taught by practicing craftspeople, and supplementary downloads like quizzes, blueprints, and other materials to help you master the skills.