When it comes to woodworking projects and wood construction, there are tons of different methods for joining two pieces of wood. Screws, nails, ages-old techniques with chisels and hand saws, and many more techniques exist, each with its own pros and cons. The biscuit joint is one such method, and it has its fair share of applications.

What is a biscuit joint?

A biscuit joint is a method of joinery that involves inserting a compressed wood chip (the biscuit) in slots cut into two corresponding pieces of wood. The oval-shaped biscuit resembles a football, and when placed into a glue-filled joint, it swells and locks the joint in place.

The slots the biscuits fit in are cut by a power tool called a biscuit joiner (also known as a plate joiner). This woodworking tool has a small circular blade that plunges into a board, leaving behind a half-moon-shaped slot. When carefully aligned, a biscuit joiner allows for perfectly hidden joinery.

Biscuit Joint Sizes and Settings

The biscuits themselves come in a few different sizes, with varying lengths and widths. This allows the user to install a biscuit joint in wood of all types and thicknesses. The general rule of thumb is to use the largest biscuit possible, as larger biscuits allow for more surface area for glue. The most common sizes are:

- FF: ½” wide, 1 ⅜” long

- 0: ⅝” wide, 1 ⅞” long

- 10: ¾” wide, 2 ⅛” long

- 20: 15/16” wide, 2 ¼” long

Biscuit joiners also have depth settings to accommodate these biscuit sizes. The user simply twists the knob to the correct depth (which is usually marked on the biscuit jointer), and the machine will automatically limit the blade’s travel at the correct depth, which allows for a tight fit and solid joint.

Biscuit jointers have adjustable fences that register against the board and control the height of the slot. By twisting the dial, the user can adjust the height and cut consistent slots against materials of the same thicknesses. This also allows the user to cut double biscuits when extra strength is necessary.

When to use a biscuit joint

Biscuit joints are ideal when ease, speed, and consistency are more important than strength. The tools to make a biscuit join are easy to use and achieve consistent results.

For instance, if someone is building a bookshelf, they could easily layout consistent and parallel shelves using a biscuit joiner. By aligning the side of the cabinet and drawing reference lines across both boards, they can mark the locations for the biscuits. After clamping a straight edge in place, they’ll be able to bore the slots in seconds.

For tabletops, biscuit joints between boards are much faster than milling tongue-and-groove joints on a router table. With wood spread along the edges of the boards, the biscuits will align them to make a very flat surface that requires just a bit of sanding.

Common Types of Biscuit Joints

Biscuit joints get a bit of criticism for their strength (or relative lack thereof), but there are quite a few applications where biscuit joints are ideal.

Joining edge grain to edge grain

The most common use for a biscuit joint is mating edge grain to edge grain, like when making a tabletop from several pieces of wood. Since the biscuit jointer cuts the slots at consistent heights, the biscuits themselves help align the boards during glue-up. They also allow a bit of wiggle room laterally, which is something you don’t get from tenons or dowels.

When it comes to woodworking projects and wood construction, there are tons of different methods for joining two pieces of wood. Screws, nails, ages-old techniques with chisels and hand saws, and many more techniques exist, each with its own pros and cons. The biscuit joint is one such method, and it has its fair share of applications.

What is a biscuit joint?

A biscuit joint is a method of joinery that involves inserting a compressed wood chip (the biscuit) in slots cut into two corresponding pieces of wood. The oval-shaped biscuit resembles a football, and when placed into a glue-filled joint, it swells and locks the joint in place.

The slots the biscuits fit in are cut by a power tool called a biscuit joiner (also known as a plate joiner). This woodworking tool has a small circular blade that plunges into a board, leaving behind a half-moon-shaped slot. When carefully aligned, a biscuit joiner allows for perfectly hidden joinery.

Biscuit Joint Sizes and Settings

The biscuits themselves come in a few different sizes, with varying lengths and widths. This allows the user to install a biscuit joint in wood of all types and thicknesses. The general rule of thumb is to use the largest biscuit possible, as larger biscuits allow for more surface area for glue. The most common sizes are:

- FF: ½” wide, 1 ⅜” long

- 0: ⅝” wide, 1 ⅞” long

- 10: ¾” wide, 2 ⅛” long

- 20: 15/16” wide, 2 ¼” long

Biscuit joiners also have depth settings to accommodate these biscuit sizes. The user simply twists the knob to the correct depth (which is usually marked on the biscuit jointer), and the machine will automatically limit the blade’s travel at the correct depth, which allows for a tight fit and solid joint.

Biscuit jointers have adjustable fences that register against the board and control the height of the slot. By twisting the dial, the user can adjust the height and cut consistent slots against materials of the same thicknesses. This also allows the user to cut double biscuits when extra strength is necessary.

When to use a biscuit joint

Biscuit joints are ideal when ease, speed, and consistency are more important than strength. The tools to make a biscuit join are easy to use and achieve consistent results.

For instance, if someone is building a bookshelf, they could easily layout consistent and parallel shelves using a biscuit joiner. By aligning the side of the cabinet and drawing reference lines across both boards, they can mark the locations for the biscuits. After clamping a straight edge in place, they’ll be able to bore the slots in seconds.

For tabletops, biscuit joints between boards are much faster than milling tongue-and-groove joints on a router table. With wood spread along the edges of the boards, the biscuits will align them to make a very flat surface that requires just a bit of sanding.

Common Types of Biscuit Joints

Biscuit joints get a bit of criticism for their strength (or relative lack thereof), but there are quite a few applications where biscuit joints are ideal.

Joining edge grain to edge grain

The most common use for a biscuit joint is mating edge grain to edge grain, like when making a tabletop from several pieces of wood. Since the biscuit jointer cuts the slots at consistent heights, the biscuits themselves help align the boards during glue-up. They also allow a bit of wiggle room laterally, which is something you don’t get from tenons or dowels.

Miter joints

Biscuits are also suitable for miter joints, as the biscuit cutter excels at cutting slots between the two mitered pieces, offering more surface area for the glue than a typical mitered joint. This is ideal for window and door casings, as well as for making picture frames, standard frame-and-panel cabinet doors, and other woodworking projects.

End-to-edge Joints

Wood end grain in solid wood doesn’t glue well, as it often soaks up the glue and dries to a fragile joint. This is another scenario where a biscuit can increase glued surface area and strengthen the end-to-edge joint. This technique can be particularly useful when installing wainscoting or building certain types of furniture like dressers, benches, or table.

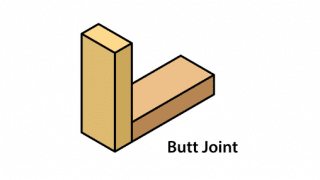

Butt joints

Biscuit joints can also strengthen an end-to-end butt joint, giving the glue in the joint something more than just the end grain to adhere to. While the joint itself probably won’t carry much weight without support underneath, it can prevent two butt ends from separating over time.

Offset joints

Many woodworkers like to add character and depth to their projects by using an offset joint to create a reveal. A reveal is when two pieces of wood are purposely offset, such as the apron on a table being inset slightly from the table legs.

Biscuit joints excel for these projects. By using the biscuit jointer to cut all the slots in the aprons, and then adjusting the fence for the slots in the legs, the user doesn’t need to measure to create consistent and even reveals on all four corners.

Double joints

For applications where a bit more strength is necessary, a double biscuit joint might do the trick. With this method, the user cuts the slot twice, adjusting the biscuit joiner after the first cut. This allows them to install two biscuits, making the joint stronger and allowing for more glue.

But, strength isn’t biscuit joinery’s main attribute. The biscuits themselves are made of compressed wood and aren’t incredibly strong, and the biscuit slots are relatively shallow compared to a mortise and tenon joint. For that reason, they’re best for light-duty applications like tabletops, bookshelves, trim work, and other similar uses. Any type of load-bearing application (other than a few books spread across a shelf) is better suited for heavy-duty joinery techniques.

Final thoughts

For quick, consistent joints, biscuit joinery certainly has its place. While it’s not the strongest form of joinery, biscuit joints are easy to set up and cut, allowing the user to keep moving and complete their project. For those reasons, biscuits are definitely worth considering for light-duty joints.

MT Copeland offers video-based online classes that give you a foundation in construction fundamentals with real-world applications, like introduction to cabinetry. Classes include professionally produced videos taught by practicing craftspeople, and supplementary downloads like quizzes, blueprints, and other materials to help you master the skills.